Chengshuo muaj milling composite machining center thiab nws cov kev paub dhau los

hauv kev tsim cov khoom siv tooj dag siab.

Yog tias koj xav tau kho cov khoom siv tooj dag, thov xa cov duab kos rau peb lub Hoobkas.Peb yuav muab kev pabcuam tshaj lij rau koj.Ua ntej, peb R & D engineers yuav muaj kev nkag siab tob txog kev siv yav tom ntej ntawm cov khoom siv tooj dag uas xav tau cov khoom tsim.

Tom ntej no, ib qho kev kuaj xyuas nruj yuav ua raws li cov khoom siv tooj dag sib txawv. Peb cov kws ua haujlwm R & D thiab cov kws kho tshuab laus yuav xaiv cov qauv tooj dag thiab cov ntaub ntawv tsim nyog raws li cov khoom siv ib puag ncig, cov qauv tsim khoom, thiab kev ua tau zoo, thiab tsim cov txheej txheem rau kev ua haujlwm.

Cov khoom siv tooj dag feem ntau siv hauv peb cov chaw ua haujlwm CNC yog raws li hauv qab no:

1. Ntshiab tooj liab

Ntshiab tooj liab feem ntau yog mos thiab ductile, thiab dilution qib ntshiab tooj liab muaj me me ntawm ntau yam alloying ntsiab. Yog li ntawd, qhov no yuav pab hloov ib lossis ntau tus yam ntxwv ntawm cov tooj liab ntshiab rau hauv cov khoom xav tau. Ib yam li ntawd, ntxiv lwm cov ntsiab lus alloying rau cov tooj liab ntshiab kuj tuaj yeem ua rau nws muaj zog.

Cov muaj pes tsawg leeg ntawm kev lag luam ntshiab tooj liab muaj kwv yees li 0.7% impurities. Raws li cov ntsiab lus sib txawv ntawm cov ntsiab lus ntxiv thiab impurities, lawv cov lej UNS yog C10100 txog C13000.

Cov tooj liab ntshiab yog qhov tsim nyog tshaj plaws rau kev tsim khoom siv hluav taws xob, uas suav nrog cov xov hlau thiab lub cev muaj zog. Tsis tas li ntawd, hom tooj liab no kuj tsim nyog rau kev lag luam tshuab xws li kev sib pauv cua sov.

2. Electrolytic tooj liab

Electrolytic tooj liab originates los ntawm cathode tooj liab, uas yog hais txog tooj liab refined los ntawm electrolysis. Feem ntau hais lus, cov txheej txheem no suav nrog kev txhaj tshuaj tooj liab rau hauv kev daws teeb meem thiab siv hluav taws xob txaus los pab ntxuav cov khoom siv tooj liab. Yog li ntawd, cov ntsiab lus impurity ntawm feem ntau electrolytic tooj liab yog qis dua li ntawm lwm qib tooj liab.

Ntawm tag nrho cov electrolytic tooj liab, C11000 yog hom ntau tshaj plaws, nrog cov hlau impurities (xws li sulfur) feem ntau tsawg dua 50 feem ntawm ib lab. Tsis tas li ntawd, lawv kuj muaj cov conductivity siab, mus txog 100% IACS (International Annealed Copper Standard).

Nws cov ductility zoo heev ua rau nws tsim nyog rau kev siv hluav taws xob, suav nrog winding, cables, xov hlau, thiab busbar.

3. Oxygen dawb tooj liab

Piv nrog rau lwm hom tooj liab, oxygen dawb tooj liab muaj yuav luag tsis muaj oxygen. Feem ntau, cov qib anaerobic tooj liab suav nrog ntau cov khoom siv hluav taws xob tooj liab siab. Txawm li cas los xij, C10100 thiab C10200 yog qhov ntau tshaj.

C10100, tseem hu ua Oxygen Free Electronic Copper (OFE), yog tooj liab ntshiab nrog cov ntsiab lus oxygen ntawm kwv yees li 0.0005%. Tsis tas li ntawd, nws kuj yog qhov kim tshaj plaws ntawm cov qib tooj liab no. Tsis tas li ntawd, C10200, tseem hu ua oxygen dawb tooj liab (OF), muaj cov ntsiab lus oxygen ntawm kwv yees li 0.001% thiab muaj kev ua haujlwm siab.

Cov khoom siv tooj liab tsis muaj oxygen yog tsim los siv cov khoom zoo cathode tooj liab los ntawm induction melting. Thaum lub sij hawm tsim cov txheej txheem, cathode tooj liab melts nyob rau hauv uas tsis yog oxidizing tej yam kev mob them los ntawm graphite da dej. Oxygen dawb tooj liab muaj cov conductivity siab thiab yog qhov tsim nyog rau kev siv hauv cov khoom siv hluav taws xob siab, nrog rau cov raj xa tawm thiab cov iav hlau ntsaws ruaj ruaj.

4. Yooj yim txiav tooj liab

Cov khoom siv tooj liab no yog tsim los ntawm ntau yam alloying ntsiab. Cov ntsiab lus tseem ceeb muaj xws li npib tsib xee, tin, phosphorus, thiab zinc. Lub xub ntiag ntawm cov ntsiab lus no pab txhim kho kev ua haujlwm ntawm cov khoom siv tooj liab.

Tsis tas li ntawd, dawb txiav cov ntaub ntawv tooj liab kuj muaj xws li tooj liab alloys xws li tooj liab thiab tooj dag. Thov nco ntsoov cov ntsiab lus hauv qab no:

Bronze yog ib qho alloy ntawm tooj liab, tin, thiab phosphorus, paub txog nws qhov hardness thiab cuam tshuam lub zog;

Brass yog ib qho alloy ntawm tooj liab thiab zinc, uas muaj kev ua haujlwm zoo thiab corrosion kuj;

Ib qho yooj yim txiav tooj liab cov ntaub ntawv tsim nyog rau kev ua ntau yam tooj liab qhov chaw, xws li machined hluav taws xob Cheebtsam, zog, bearings, automotive hydraulic Cheebtsam, thiab lwm yam.

5. Customized tooj dag profiles nrog tshwj xeeb piv

Customized ua cov khoom siv tooj dag uas ua tau raws li cov kev xav tau ntawm ntau lub teb chaws lossis kev lag luam.

Piv txwv li, cov hlau lead-dawb bismuth tooj dag customized los ntawm Chengshuo rau cov neeg siv khoom yog cov hlau lead-dawb thiab yooj yim los txiav tooj liab. Nws tuaj yeem raug txiav yam tsis muaj cov hmoov txhuas, yog li ua tau raws li qhov xav tau ntawm kev ua haujlwm thiab ua tiav qhov ci ntsa iab nrog kev ua siab ntev siab. Nws yuav tsum yooj yim txiav thiab tsis muaj burrs.

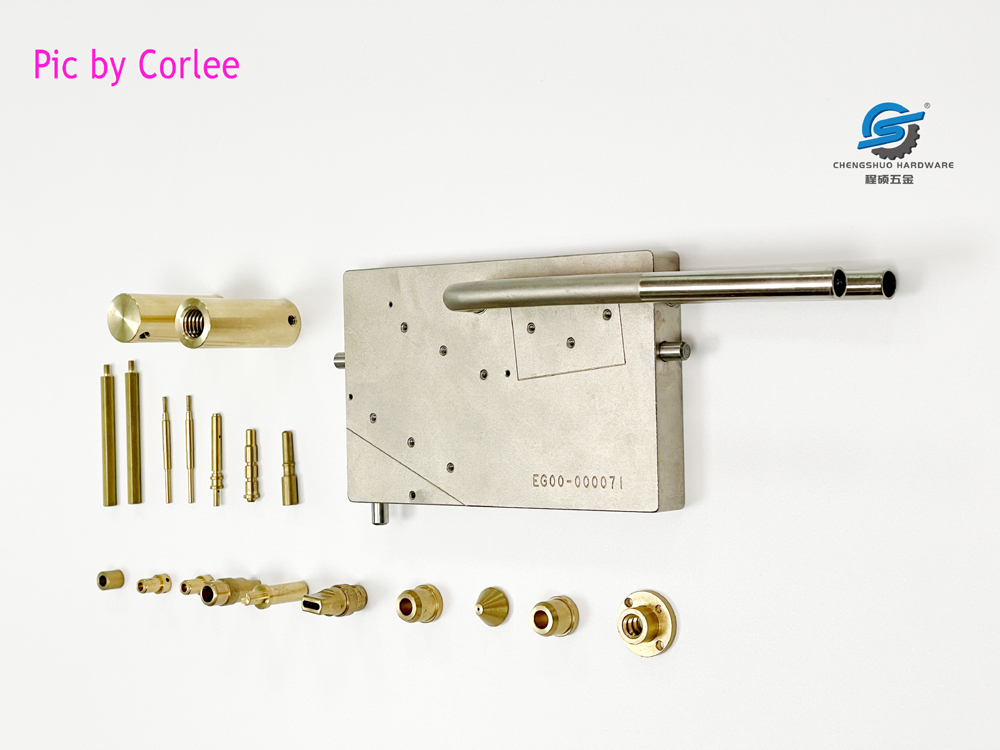

CNC machining tshuab rau cov khoom siv tooj liab

1. Copper qhov chaw milling ua

CNC milling yog cov txheej txheem machining tsis siv neeg uas tuaj yeem tswj tau qhov txav thiab pub tus nqi ntawm cov cuab yeej sib hloov. Thaum CNC milling tooj liab, lub cuab yeej tig thiab txav mus rau saum npoo ntawm cov khoom siv tooj liab. Tom qab ntawd, cov khoom siv tooj liab ntau dhau maj mam muab tshem tawm kom txog thaum nws tsim cov duab thiab qhov loj me.

CNC milling yog txoj kev siv ntau tshaj plaws hauv tooj liab alloy machining, raws li tooj liab alloys muaj zoo machining thiab muaj peev xwm ua tau precision thiab complex qhov chaw. Ob chav edged hard alloy kawg mills feem ntau yog siv los zeb tooj liab.

Cheng Shuo tus kws kho tsheb kuj siv cov khoom siv ua tus kheej kom ua tiav cov khoom siv tooj liab nrog cov qauv tsim sib txawv, thiab muaj kev paub nplua nuj hauv kev siv ntau yam qauv xws li grooves, qhov, thiab tiaj tus contours.

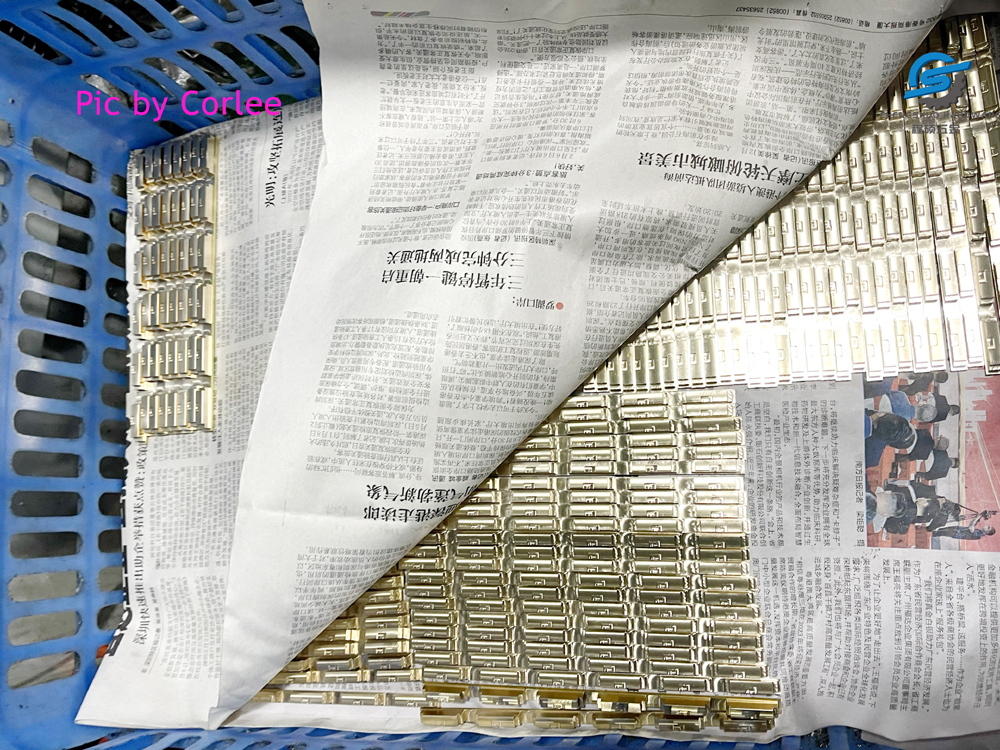

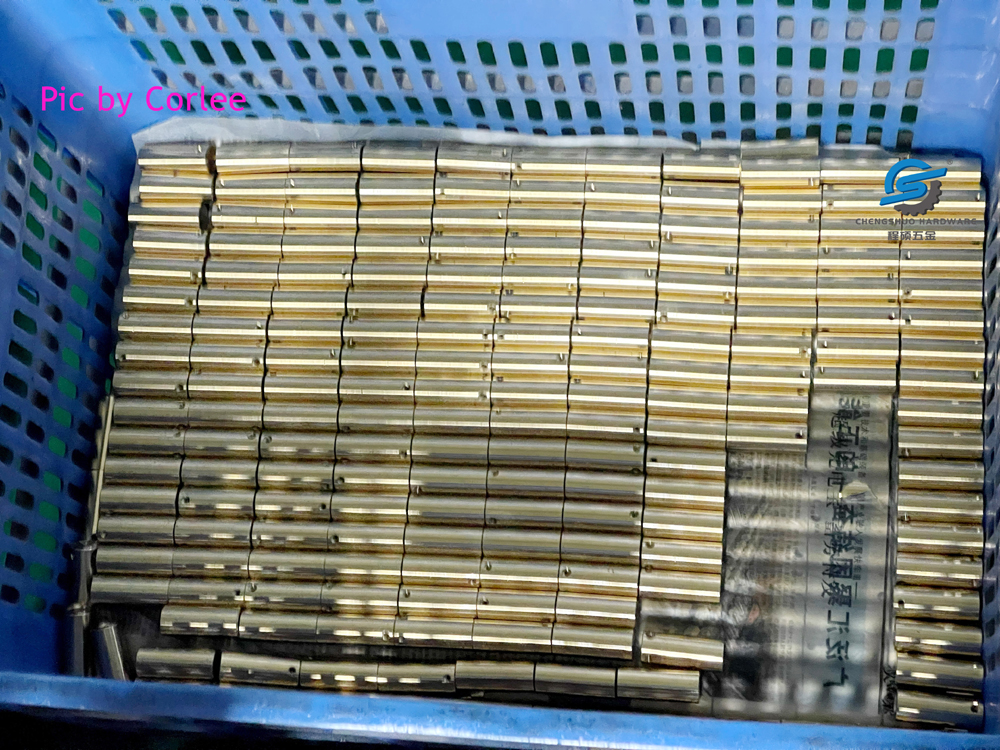

2. Tig ua cov khoom siv tooj liab

Chengshuo hardware yog ib tug kws dhos tshuab dhos laus nrog kev nplua nuj nyob rau hauv kev tig. Cov khoom siv tooj liab yog tsau rau hauv cov cuab yeej txiav qhov chaw ruaj khov, thiab cov khoom siv tooj liab tau tig ntawm qhov teeb tsa ceev. Nrog kev pab los ntawm kev xa cov kua dej, cylindrical tooj dag qhov chaw tiav.

Tig yog tsim rau ntau yam tooj liab alloys thiab tuaj yeem tsim cov khoom siv tooj liab ceev ceev. Tsis tas li ntawd, cov txheej txheem no kuj muaj txiaj ntsig zoo. Yog li ntawd, CNC tig tooj liab yog tsim rau kev tsim ntau yam khoom siv hluav taws xob thiab khoom siv hluav taws xob, xws li cov khoom sib txuas, cov li qub, busbars, cov dab dej kub, thiab lwm yam.

Post lub sij hawm: Nov-29-2023