Txhawm rau siv cov khoom siv hlau kho vajtse, peb cov engineers yuav ua tib zoo xaiv cov txheej txheem rau kev siv ntau yam khoom.

Cov txheej txheem ua tiav rau cov khoom siv kho vajtse tam sim no suav nrog:

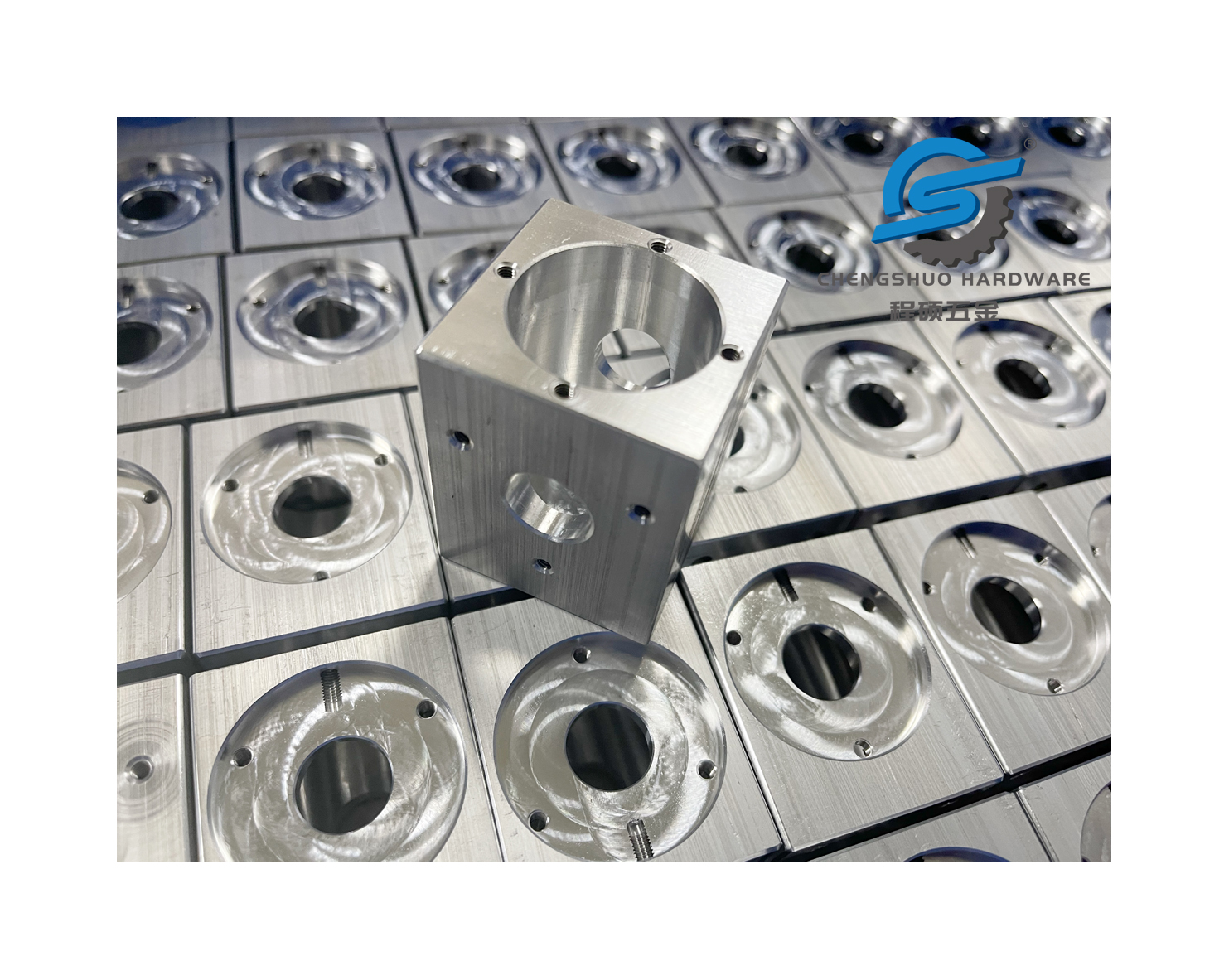

1. CNC machining

CNC tig, milling, xuas nrig ntaus, CNC cutting processing yog hais txog cov txheej txheem ntawm kev txiav cov khoom ua haujlwm rau hauv cov duab uas xav tau thiab loj los ntawm cov cuab yeej txiav. Kev txiav cov txheej txheem xws li tig, milling, drilling, thiab lwm yam.

Ntawm lawv, txoj siav yog siv cov cuab yeej txiav rau ntawm lub tshuab dhos ua cov txheej txheem ua haujlwm rotating, uas tuaj yeem tsim ntau txoj kab uas hla, qhov ntev, thiab cov duab ncej;

Milling yog siv cov cuab yeej txiav rau ntawm lub tshuab milling los tig thiab txav mus ua haujlwm, uas tuaj yeem tsim ntau yam duab tiaj tus thiab convex concave ntawm qhov chaw;

Drilling yog siv cov cuab yeej txiav rau ntawm lub tshuab drilling los laum qhov hauv cov khoom ua haujlwm, uas tuaj yeem tsim cov qhov ntawm ntau txoj kab uas hla thiab qhov tob.

Chengshuo tau siv peb tus kheej CNC machining chaw, uas tuaj yeem muab cov kev pabcuam ib-nres rau cov khoom lag luam customized nrog cov khoom sib txawv.

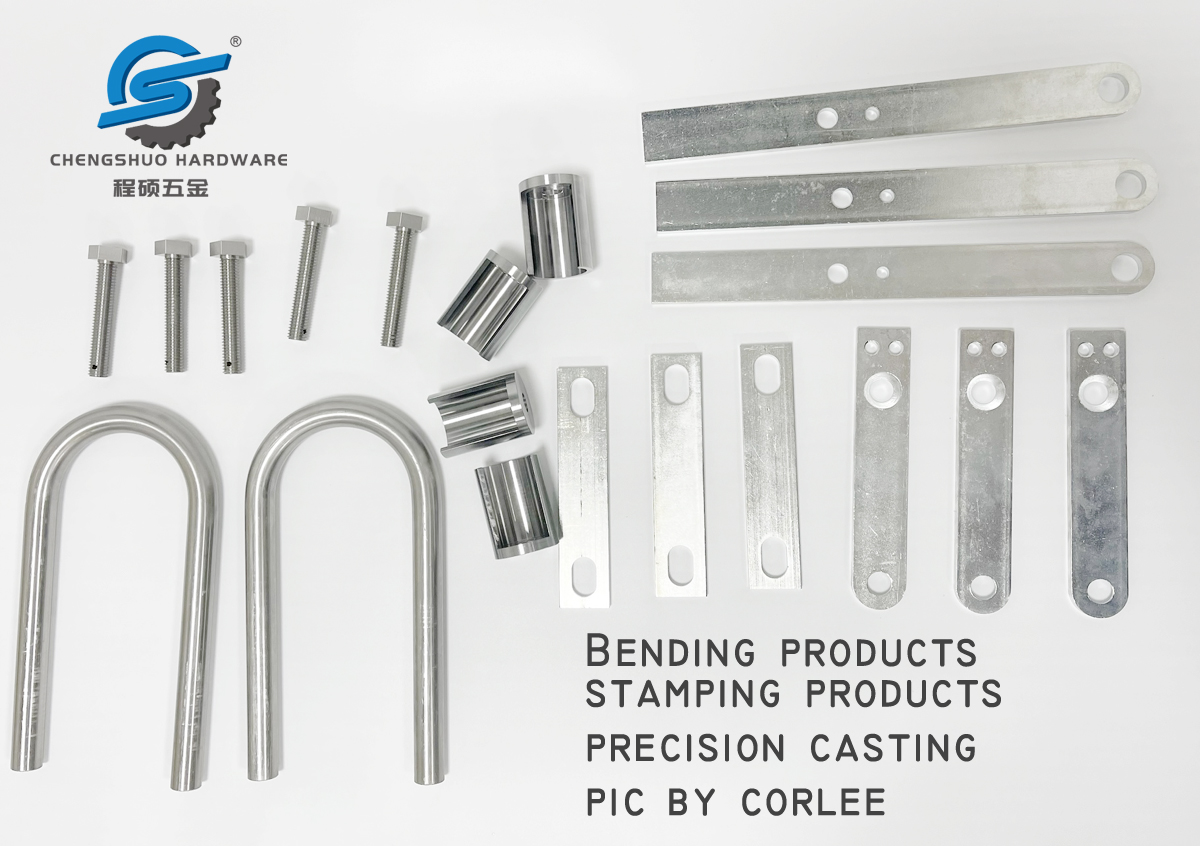

2. Stamping processing – Stamping center

Stamping processing yog hais txog cov txheej txheem ntawm stamping hlau los xij rau hauv cov duab uas xav tau los ntawm stamping pwm. Cov txheej txheem stamping feem ntau suav nrog kev txiav, xuas nrig ntaus, khoov, thiab lwm yam. Ntawm lawv, kev txiav yog txiav cov ntawv hlau raws li qhov loj me kom tau txais qhov loj me ntawm qhov chaw tiaj tus. Punching yog siv cov pwm ntawm lub tshuab xuas nrig ntaus rau cov ntawv hlau, uas tuaj yeem tau txais ntau yam duab thiab qhov ntau thiab tsawg ntawm qhov; Khoov yog siv lub tshuab dabtsi yog khoov los khoov cov ntawv hlau, uas ua rau muaj ntau yam duab thiab cov kaum sab xis ntawm qhov chaw.

Stamping tuag yog cov txheej txheem tshwj xeeb uas siv los ua cov txheej txheem txias txias los ua cov khoom siv (hlau lossis tsis yog hlau) rau hauv qhov chaw (lossis cov khoom tiav), hu ua txias stamping tuag (feem ntau hu ua txias stamping tuag)

Common classification ntawm stamping pwm:

(1) Ib qho txheej txheem pwm yog pwm uas ua tiav ib qho txheej txheem stamping nyob rau hauv ib qho stroke ntawm ib lub xovxwm.

(2) Cov pwm sib xyaw tsuas muaj ib lub chaw ua haujlwm xwb, thiab hauv ib qho kev mob stroke ntawm cov xovxwm, nws yog pwm ua tiav ob lossis ntau qhov txheej txheem stamping ib txhij ntawm tib lub chaw ua haujlwm.

(3) Progressive tuag (tseem hu ua kev tuag tas mus li) muaj ob lossis ntau qhov chaw ua haujlwm nyob rau hauv cov kev taw qhia ntawm raw khoom noj. Nws yog cov pwm uas ua tiav ob los yog ntau tshaj cov txheej txheem stamping ntawm cov chaw ua haujlwm sib txawv hauv ib qho stroke ntawm xovxwm.

(4) Cov pwm hloov pauv sib xyaw ua ke cov yam ntxwv ntawm cov txheej txheem pwm thiab cov pwm pwm. Los ntawm kev siv lub tshuab hluav taws xob hloov hluav taws xob, cov khoom tuaj yeem hloov pauv sai sai hauv cov pwm, txhim kho kev tsim khoom zoo, txo cov nqi tsim khoom, txuag cov nqi khoom, thiab ua kom ruaj khov thiab txhim khu kev qha zoo.

3. Vuam ua

Welding processing yog hais txog cov txheej txheem ntawm kev sib txuas ob lossis ntau dua cov ntaub ntawv hlau los ntawm cov cua sov, melting, los yog pressurization. Cov txheej txheem welding feem ntau muaj xws li arc vuam, fluorine arc vuam, roj vuam, thiab lwm yam. Ntawm lawv, arc vuam siv cov arc cua sov tsim los ntawm lub tshuab vuam kom yaj thiab txuas cov ntaub ntawv hlau ua ke; ammonia arc vuam siv cov cua sov uas tsim los ntawm ammonia arc nyob rau hauv kev tiv thaiv ntawm ib tug shielding roj kom yaj thiab txuas cov ntaub ntawv hlau ua ke; gas welding siv cov nplaim hluav taws kub uas tsim los ntawm kev sib tsoo ntawm cov pa kom yaj thiab txuas cov ntaub ntawv hlau ua ke.

4. Bending processing – dabtsi yog khoov chaw

Txoj kev khoov yog hais txog cov txheej txheem ntawm kev khoov cov ntaub ntawv hlau rau hauv cov duab uas xav tau los ntawm lub tshuab khoov. Cov txheej txheem dabtsi yog khoov muaj xws li V-bending, U-bending, Z-bending, thiab lwm yam. Ntawm lawv, V-shaped dabtsi yog khoov yog hais txog dabtsi yog khoov cov ntawv hlau ntawm ib lub kaum ntse ntse los ua V-shaped; U-shaped dabtsi yog khoov hais txog kev khoov cov ntawv hlau ntawm ib lub kaum ntse ntse los ua ib qho U-puab; Z-bending yog txheej txheem ntawm kev khoov cov ntawv hlau ntawm ib lub kaum ntse ntse los tsim Z-zoo li

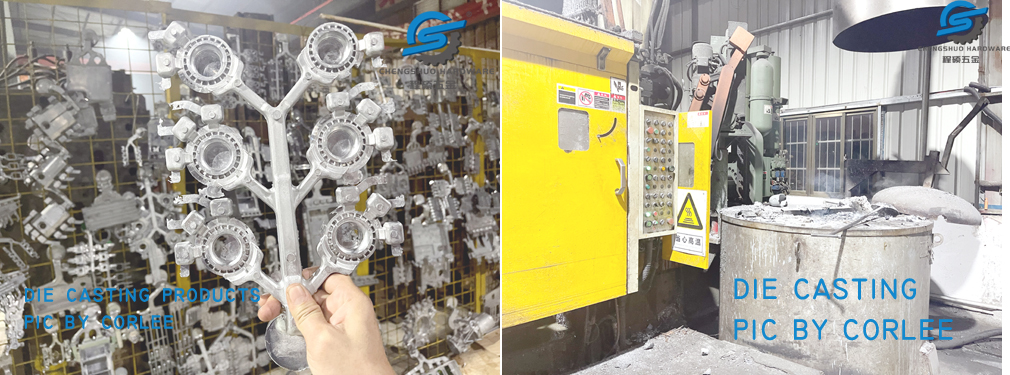

5. Tuag casting ua - Tuag casting chaw

Feem ntau siv los ua cov khoom siv kho vajtse ntxhib. Tuag casting yog lub npe luv rau kev siab casting. Nws yog ib txoj hauv kev sau cov kab noj hniav ntawm cov pwm tuag casting nrog cov kua lossis cov kua hlau semi-kua ntawm kev kub siab thiab nrawm nrawm kom tau txais cov casting. Tuag casting pwm siv yog hu ua tuag casting pwm.

6. Hlau txiav ua

Chengshuo Hardware muaj nws cov khoom siv hlau txiav. Kab txiav yog ib qho luv luv rau kab txiav, xa mus rau txoj kev ua. Nws tsim nyob rau hauv lub hauv paus ntawm hluav taws xob tawm perforation thiab tsim ua. Nws yog ib txoj hauv kev ua haujlwm uas siv cov xaim hlau txav (molybdenum xaim, tooj liab, lossis hlau alloy) ua cov xov hlau electrode, thiab ua kom kub siab los ntawm cov hluav taws xob hluav taws xob tawm ntawm cov xov hlau electrode thiab cov khoom ua haujlwm, ua rau cov hlau yaj lossis vaporize, sib sau. txiav seams, thiab yog li txiav tawm qhov seem.

Tom qab ntau yam kev ua, cov khoom tau txais ntau yam kev kho mob saum npoo.

Kev kho deg yog hais txog cov txheej txheem ntawm kev ntxuav saum npoo, tshem tawm xeb, tiv thaiv corrosion, txau thiab lwm yam kev kho mob rau cov khoom siv kho vajtse. Cov kev kho saum npoo feem ntau muaj xws li pickling, electroplating, spraying, thiab lwm yam. Ntawm lawv, kev ntxuav cov kua qaub yog siv cov kua qaub rau corrode thiab ntxuav cov khoom siv kho vajtse, tshem tawm cov oxides thiab cov av ntawm qhov chaw. Electroplating yog siv cov electrolysis los tso cov hlau ions rau saum npoo ntawm cov khoom siv kho vajtse los tsim cov yeeb yaj kiab tiv thaiv thiab txhim kho lawv cov kev tiv thaiv corrosion; Txau yog siv cov cuab yeej txau kom sib npaug ntawm cov xim pleev xim rau saum npoo ntawm cov khoom siv kho vajtse, tsim cov yeeb yaj kiab tiv thaiv los txhim kho lawv qhov zoo nkauj thiab huab cua tsis kam.

Post lub sij hawm: Dec-13-2023