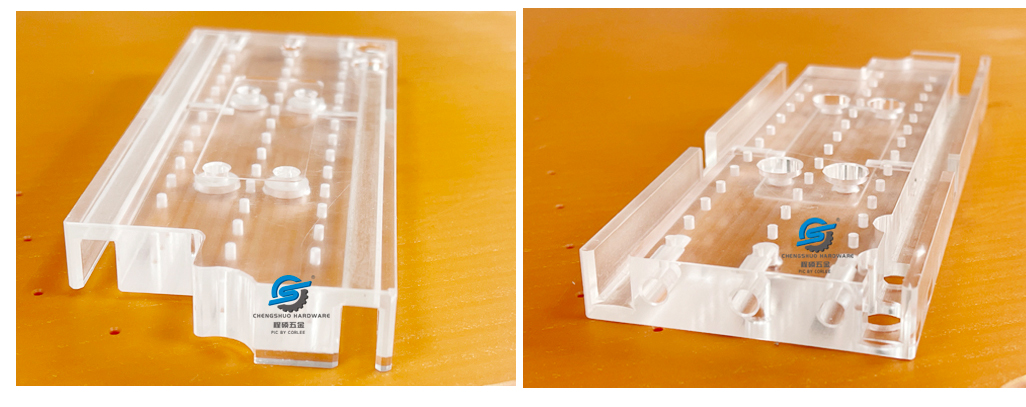

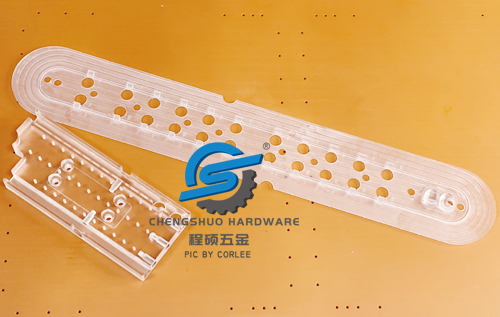

CNC machining ntawm cov khoom acrylic tuaj yeem ua tiav ntau cov qauv, txo cov kab nrib pleb hauv cov khoom siv acrylic thaum lub sijhawmtshuab, thiab ua tau raws li qhov xav tau ntawm cov khoom siv siab.

Polymethyl methacrylate (CH3│—[—CH2—C—]-Txoj kev COOCH3) muaj cov khoom zoo txhua yam, suav nrog qhov zoo tshaj plaws ntawm cov yas dav dav. Nws tensile, dabtsi yog khoov, thiab compression zog yog siab tshaj polyolefin, thiab kuj siab tshaj polystyrene, polyvinyl chloride, thiab lwm yam., tab sis nws tej yam toughness yog tsis zoo. Tab sis nws kuj yog me ntsis zoo dua li polystyrene.physical zog.

PMMA muaj zog txhua yam: qhov txheeb ze molecular loj ntawm PMMA yog txog 2 lab. Nws yog ib tug ntev-chain polymer, thiab cov chains tsim cov molecule yog mos heev. Yog li ntawd, PMMA muaj lub zog muaj zog thiab tiv taus kev ncab thiab cuam tshuam. 7 mus rau 18 lub sij hawm siab dua li cov iav zoo tib yam.Nws muaj ib hom iav organic uas tau ua kom sov thiab ncab, nyob rau hauv uas cov ntu molecular tau teem rau hauv ib qho kev txiav txim zoo, uas ua rau cov khoom muaj zog zoo.

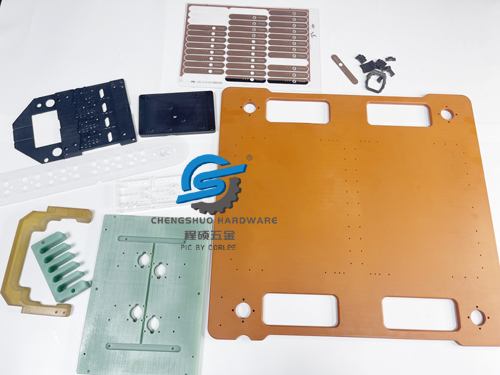

Acrylic feem ntau yog siv hauv kev lag luam los tsim thiab tsim cov cuab yeej ntsuas vaj huam sib luag thiab npog, kuj rau ntau yam khoom siv phais thiab kho mob, khoom siv hauv tsev: chav dej, khoom siv tes ua, tshuaj pleev ib ce, brackets, thoob dej yug ntses, thiab lwm yam.

Thaum siv CNC ua cov khoom siv acrylic, yuav tsum tau them sai sai rau cov ntsiab lus hauv qab no:

1. CNCProgramming Design Rau AcrylicTshuab dhosKev ua haujlwm

Rau acrylic (Polymethyl methacrylate, PMMA), programming cov ntsiab lus ntawm cov khoom yuav tsum tau tsim raws li cov duab ntawm cov khoom, xws li cov cuab yeej pub ceev thiab kev sib hloov ceev thaum lub sij hawm.tshuabua. Raws li cov duab tiag tiag ntawm cov khoom, cov txheej txheem programming thiab ntws yuav tsum tau ua kom zoo kom txo qis kev puas tsuaj thaum lub sijhawm ua haujlwm.

Thaum siv CNCtshuabacrylic, nws yog ib qho tseem ceeb heev los teeb tsa tus nqi noj kom raug. Yog tias tus nqi pub ceev dhau, PMMA tuaj yeem tawg vim qhov kev txiav siab heev. Cov nqi noj ceev kuj tuaj yeem ua rau cov khoom txav tawm ntawm qhov chaw ua haujlwm los yog tawm ntawm qhov tsis zoo; qeeb pub tus nqi kuj tuaj yeem tsim qhov tsis raug nrog qhov ntxhib, tsis tiav.

2. Kev xaiv cov cuab yeej hauv kev ua acrylic yuav tsum tsim nyog

Ua cov ntawv acrylic yuav tsum tau siv cov cuab yeej tsim nyog. Nyob ntawm qhov zoo ntawm cov cuab yeej, cov cuab yeej siv feem ntau muaj xws li cov mills kawg, pob qhov ntswg cutters, flat cutters, thiab lwm yam. Cov cutter tiaj tiaj yog tsim rau kev txiav thiab tu thaj chaw loj, qhov kawg zeb yog nyob rau hauv cov duab ntawm lub kaum sab xis thiab tsim nyog. rau kev ua cov npoo ntawm cov ntawv nyeem thiab cov duab, thiab lub pob qhov ntswg cutter yog nyob rau hauv cov duab ntawm ib tug arc thiab yog haum rau kev ua tiav heev meej qauv thiab nkhaus.

Cov khoom ntawm riam kuj tseem ceeb heev. Piv txwv li, high-speed steel txiav acrylic, tab sis tsis muab qhov chaw zoo. Cov cuab yeej pob zeb diamond tuaj yeem txhim kho qhov chaw tiav tab sis kim heev. Carbide feem ntau yog cov khoom xaiv rau CNC txiav acrylic.

Rau CNC machining acrylic, nws kuj pom zoo kom siv lub txiav ntug rake lub kaum sab xis ntawm 5 degrees thiab ntxiv lub kaum sab xis ntawm 2 degrees.

Ntxiv nrog rau cov cuab yeej txiav, yuav tsum tau them sai sai rau kev txiav qhov tob, ceev, thiab lwm yam thaum ua cov khoom siv acrylic kom ntseeg tau tias cov qauv ntawm cov khoom siv acrylic tsis puas. Acrylic feem ntau yog cov khoom tsis yooj yim. Thaum lub sij hawm CNC txiav, siv cov cuab yeej tsim nyog thiab qhov tsim nyog txiav qhov tob thiab ceev tuaj yeem zam cov khoom seem los ntawm cov khoom tawg lossis zawv zawg. Nyob rau hauv tas li ntawd mus txiav, nws yog tsim nyog los tuav qhov tseeb ua ceev thiab qhov tob ntawm lub cuab tam, thiab sim xyuas kom meej tias cov khoom qauv tsis puas, xws li fragmentation, disconnection, thiab lwm yam nyob rau tib lub sij hawm, yuav tsum tau them nyiaj mloog mus rau minimizing. Thaum tshav kub kub thiab hluav taws xob zoo li qub thaum ua.

3. Siv qhov raug laum ntsis thiab bevel

Nco ntsoovtuslaum tuaj yeem tsim qhov zoo hauv acrylic los ntawm kev xaiv cov khoom siv tho zoo. Carbide yog ib qho kev xaiv zoo heev rau kev drilling acrylic, thiab ntau lub tuam txhab siv O-groove kawg zeb laum khoom tshwj xeeb tsim los txiav thiab drilling acrylic. Tsis tas li ntawd, cov cuab yeej laum yuav tsum ua kom ntse, npub laum cov khoom yuav tsim cov npoo tsawg dua qhov huv thiab tuaj yeem yooj yim ua rau muaj kev ntxhov siab tawg thiab tawg.

Thaum CNC machining acrylic, nws yog qhov zoo tshaj plaws los siv lub bevel nrog lub laum me ntsis. Txhawm rau tiv thaiv lub laum me ntsis los ntawm kev puas tsuaj rau cov khoom ntawm cov khoom siv acrylic, nws yuav tsum tau tilted downward raws txoj kab nqes kom tiv thaiv kev puas tsuaj thiab ua kom lub ntsej muag du.

Nyob rau tib lub sijhawm, txiav qhov tob thiab kev taw qhia yuav tsum tau saib xyuas. Kev sib hloov ntawm cov cuab yeej CNC: sab laug thiab sab xis, los yog counterclockwise thiab clockwise, yuav tsum tau ua kom haum rau cov khoom kom ntseeg tau tias qhov tseeb ntawm cov khoom siv thiab tsim kev ua haujlwm.

Post lub sij hawm: Jan-16-2024