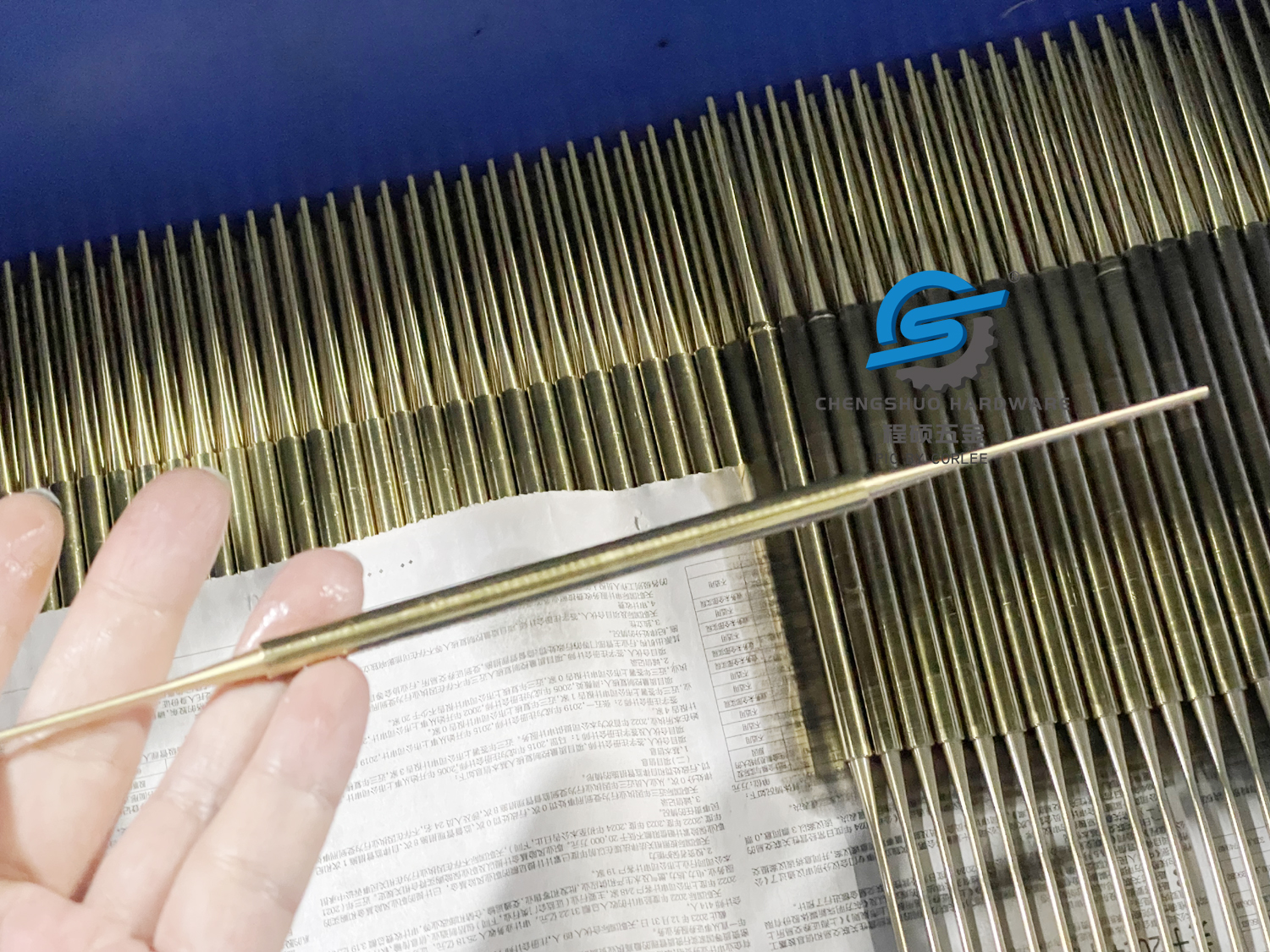

Brass Thimble Fixed Pin machined los ntawm Chengshuo 5 tsib axis tsis siv neeg tshuab dhos-Los ntawm Corlee

Kev caiBrass Thimble Tsau Pin Machining Factory CNC Milling TigChengshuo Hardware Machined

Txheej txheem cej luam ntawm cov txheej txheem machining siv tsib-axis tsis siv neeg tshuab dhos:

1. Kev teeb tsa: Npaj tsib-axis tsis siv neeg tshuab dhos rau kev ua haujlwm machining, kom ntseeg tau tias cov cuab yeej ua haujlwm thiab cov cuab yeej txiav tau raug ntsia thiab ua kom zoo.

2. Chaw thau khoom: Thawv cov khoom siv tooj dag rau hauv lub tshuab dhos, ua kom ruaj khov kom txo qis kev vibration thiab xyuas kom meej meej thaum lub sijhawm ua haujlwm.

3. Tool txoj kev programming: Tsim ib lub cuab yeej txoj kev pab cuam siv tsib-axis muaj nuj nqi kom zoo tshuab cov complex nta ntawm tooj dag ejector pin kho tus pin.

4. Tig thiab Milling: Siv lub tshuab dhos tsib-axis los ua txoj haujlwm tig thiab milling nyob rau hauv ib chav tsev, tso cai rau cov geometries complex, undercuts, thiab lwm yam complex nta yuav machined.

5. Cov cuab yeej hloov pauv: Siv cov cuab yeej hloov pauv tsis siv neeg ntawm lub tshuab dhos hloov ntawm cov cuab yeej sib txawv raws li qhov xav tau ntawm ntau yam txheej txheem xws li tig, drilling, thiab milling.

6. Kev Tswjhwm Zoo: Kev tswj xyuas kev ua tau zoo yog siv thaum lub sijhawm ua haujlwm kom ntseeg tau tias cov tshuab tooj dag thimble tuav cov pins ua tau raws li qhov ntsuas qhov ntev thiab qhov yuav tsum tau ua tiav.

7. Nto Finishing: Yog tias tsim nyog, ua txhua yam tsim nyog nto ua haujlwm xws li polishing lossis deburring kom tau qhov zoo ntawm qhov chaw.

Siv tsib-axis tsis siv neeg tshuab dhos rau tshuab tooj dag ejector pins muaj qhov zoo ntawm kev ua kom yooj yim dua thiab muaj peev xwm ua kom lub tshuab nyuaj geometries hauv ib chav tsev, thaum kawg pab kom ua tau zoo thiab raug.

Yog tias koj muaj cov qauv tsim tshwj xeeb lossis kev ua siab ntev rau koj cov tooj dag ejector pins, nws yog ib qho tseem ceeb kom ntseeg tau tias qhov programming thiab teeb tsa ntawm koj lub tshuab dhos tsib-axis tsis siv neeg yog kho kom haum raws li cov kev qhia tshwj xeeb.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias qhov tshwj xeeb machining cov haujlwm thiab qhov tsis zoo rau tooj dag ejector pins yuav txawv raws li kev tsim tshwj xeeb, kev kam rau siab thiab qhov yuav tsum tau ua kom tiav. Tsis tas li ntawd, siv cov cuab yeej txiav tsim nyog, machining speeds, thiab tooj dag machining pub yog qhov tseem ceeb kom tau txais cov txiaj ntsig zoo.